#Control Valves Market size

Explore tagged Tumblr posts

Text

Control Valves Market : Global Demand Analysis & Opportunity Outlook 2029

#Control Valves Market#Control Valves Market size#Control Valves Market growth#Control Valves Market application#Control Valves Market Control Valves Market

0 notes

Text

The Untapped Potential of the Idle Air Control Valve Market

The "Idle Air Control Valve Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Idle Air Control Valve Market?

Market Analysis and Insights :

Global Idle Air Control Valve Market

Idle air control valve market is expected to reach USD 15,094.23 million by 2028 witnessing market growth at a rate of 13.90% in the forecast period of 2021 to 2028. Data Bridge Market Research report on idle air control valve market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth.

When the engine of a stationary vehicle is operating, an idle air control valve, abbreviated as IAC, modifies the amount of air flowing through the engine. It is commonly known as idling to run the engine while the vehicle is not in motion. Typically, this happens while waiting for others, stopping at a traffic light. Technically speaking, the engine operates without any cargo other than engine accessories at the time of idling.

Increasing expansion of production in the automobile sector across the globe, rise in the number of research and development initiatives that lead to the development of new products and increase the scope of end-use applications, growing focus of companies on decreasing the overall weight of automobiles by integrating electronic components in place of manual components are some of the major as well as vital factors which will likely to augment the idle air control valve market in the projected timeframe of 2021-2028. On the other hand, increasing levels of disposable income of the people along with growing number of initiatives by the government to attract foreign direct investment and rising production of the product which will further contribute by generating massive opportunities that will lead to the growth of the idle air control valve market in the projected timeframe mentioned above.

Lesser air density will likely to act as a market restraint factor for the growth of the idle air control valve in the above mentioned projected timeframe. This idle air control valve market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on idle air control valve market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Idle Air Control Valve market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Idle Air Control Valve Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-idle-air-control-valve-market

Which are the driving factors of the Idle Air Control Valve market?

The driving factors of the Idle Air Control Valve market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Idle Air Control Valve across various industries further propel market expansion.

Idle Air Control Valve Market - Competitive and Segmentation Analysis:

Global Idle Air Control Valve Market, By Type (Pulse Solenoid Valve Type, Rotary Solenoid Valve Type, Stepping Motor Type), Sales Channel (Original Equipment Manufacturers (OEM), Aftermarket), End Use (Light Commercial Vehicles, Heavy Commercial Vehicles, Passenger Cars, Two and Three Wheelers, Sports Cars), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2031.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Idle Air Control Valve market?

The major players covered in the idle air control valve market report are Robert Bosch GmbH; BorgWarner Inc.; Continental AG; EDELBROCK, LLC.; GB Remanufacturing, Inc.; DENSO CORPORATION.; Hitachi Automotive Systems, Ltd.; Kinsler Fuel Injection; Tenneco Inc.; RUIAN CITY YANGYU MOTOR VEHICLE PARTS Co.,Ltd.; AISIN SEIKI Co., Ltd.; Mikuni Corporation.; NINGBO MIDLAND AUTO PARTS CO.,LTD; Guangzhou Marvine Auto Parts Co., Ltd.; Jiangsu Great Industrials (Group) Corp.Ltd.; Tridon Australia; Ruian Fanwei Auto Parts Co.,Ltd.; Wenzhou Guocheng Electrical Parts Co.,ltd.; Ruian Kingway Auto Parts Manufacturing Co.,Limited; PUCHENG SENSORS(SHANGHAI)CO., LTD.; among other domestic and global players.

Short Description About Idle Air Control Valve Market:

The Global Idle Air Control Valve market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Idle Air Control Valve. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Idle Air Control Valve Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Idle Air Control Valve in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Idle Air Control Valve Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Idle Air Control Valve market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Idle Air Control Valve Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Idle Air Control Valve market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Idle Air Control Valve?

What are the upcoming industry applications and trends for Idle Air Control Valve market?

What Are Projections of Global Idle Air Control Valve Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Idle Air Control Valve?

What are the raw materials used for Idle Air Control Valve manufacturing?

How big is the opportunity for the Idle Air Control Valve market?

How will the increasing adoption of Idle Air Control Valve for mining impact the growth rate of the overall market?

How much is the global Idle Air Control Valve market worth? What was the value of the market In 2020?

Who are the major players operating in the Idle Air Control Valve market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Idle Air Control Valve Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-idle-air-control-valve-market

Detailed TOC of Global Idle Air Control Valve Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Idle Air Control Valve Market By Type

Idle Air Control Valve Market By Function

Idle Air Control Valve Market By Material

Idle Air Control Valve Market By End User

Idle Air Control Valve Market By Region

Idle Air Control Valve Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-idle-air-control-valve-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Global Emulsion Breaker Market �� Industry Trends and Forecast to 2030

Global Waterproofing Membrane Market – Industry Trends and Forecast to 2029

Global Computer Assisted Coding Market – Industry Trends and Forecast to 2031

Global Idle Air Control Valve Market – Industry Trends and Forecast to 2028

Global Acanthamoeba Keratitis Treatment Market - Industry Trends and Forecast to 2028

#Idle Air Control Valve Market#Idle Air Control Valve Market Size#Idle Air Control Valve Market Share#Idle Air Control Valve Market Trends

0 notes

Text

0 notes

Link

#market research future#control valve market size#control valve market analysis#control valve market growth#control valve market forecast

0 notes

Note

Sorry you’ve been asked this repeatedly… but how is Concord, and many high-budget game cancellations, going to smoke up to investors/execs and change things? Will investors en masse just start pulling out of games industry altogether? I see you repost Today on Steam sometimes and market over-saturation seems like an actual crisis at this point.

I mean, you're exactly right. I don't understand how investors are sticking around anymore. You talk about market over-saturation and something that has spooked me for years is just how many publishers give away games or at least put them on deep discount.

Like, EGS, right. In three years they have given away almost 450 games. They give away so many games for free that I've actually stopped paying attention because it's clear I'm rarely using the client. But I've never given them a penny, and my 4-year-old EGS library is already one third the size of my 20 year old Steam library.

Now, you could say that's because Epic is burning the candle at both ends trying to shake Valve's market lead, but we could also talk about something like, say, Twitch Prime. I get a low income discount on Amazon Prime, so I get free shipping, Prime Video, and Twitch Prime for like $5 a month.

And Twitch Prime includes free games every month, right? Normally that's through some kind of terrible Amazon App for Windows, something both Twitch and Amazon seem to bury given I've never seen a download link anywhere in my entire life. Even if I knew where to download, I wouldn't do it, given I'm sure it's loaded full of tracking and telemetry. But on top of the usual Amazon App games, they've also started including keys for games on EGS and GOG.

So for $5 a month I've been getting 5-10 games on three different storefronts, including ones I'm actually going to install and play games through. And games I actually want to play, too, like Industria (GOG), Arcade Paradise (GOG), Loop Hero (EGS), Ghost Song (GOG), Shredder's Revenge (EGS), etc.

On top of the 2-3 games EGS normally gives away per month, on top of whatever else may be happening elsewhere. GOG may be giving away its own free game as part of a sale promo, for instance. So if we're talking annually, I pay $60 a year for Twitch Prime for roughly 144 games all put together. If you subtract Prime, that's still probably over 30 games a year, totally free.

And then you figure out places like Humble and Fanatical, entire storehouses that specialize in very cheap bundles.

At some point it's not even "for gamers on a budget." This is just the way the industry is now. Even games that sell well will plummet in price and end up in bundles or even just get given away for free. Deathloop, Outer Worlds, Evil Within 2, Plague Tale, Dragon Age Inquisition, Midnight Suns, Callisto Protocol, Arkham Knight, Control, Nioh, Prey...

I did not pay a penny for these games, but I own them. A consumer is very happy with that but it does not seem like a sign of a healthy industry. That is money being spent and spent and spent and spent, but it's not going back in to develop new games. It feels like this industry is hanging by the thread of FOMO alone, because if you can wait a year, maybe two, either you'll get a game straight up for free, or at least for 75-80% off.

Who would actually invest in an industry that has been bleeding so violently for so many years?

7 notes

·

View notes

Text

Steam Controller - Thoughts

Splurged on the thingy on eBay a while back, been messing with it for a few days, now.

I can see the appeal, especially for anything that isn't a typical third or first-person game, or anything that qualifies as your typical Controller Fare. Swapping the right joystick with a trackpad is a bold move that makes menuing or engaging with games that don't have native gamepad support a breeze, but it also makes everything else harder. Forget trying to perform snap-turns or quick aim corrections in a shooter; what feels like a small surface when you're looking at it feels like the mother of all trackpads, when your eyes are on the screen. If you're a fan of punchier titles, you definitely have to bring your tracking sensitivity all the way down.

Or, well, it's either that, or you spend weeks coaching yourself to replace the thumb sweeps you'd perform on a joystick with tiny little flicks across the textured surface. It's a very fiddly device that's almost nothing without Steam's provided software companion - and especially without Steam Input. If it weren't for Valve's pie-in-the-sky project to universalize controller inputs, the very idea of tackling something like a Civilization game with a gamepad would feel like pure insanity.

In a lot of ways, it's like I gave myself a precision multitool and now have to calibrate it for every single use case I run into, as opposed to Sony's very one-size-fits-all approach to game controllers. Or, if you'd like me to sound even more pedantic, I could say the Steam Controller is the Linux of game controllers.

Oh, and kudos to Valve for designing a controller dongle of respectable size, for once. It's about the size of one of the smaller USB stick formats on the market and just a little thicker.

3 notes

·

View notes

Text

Students strive for “Balance!” in a lively product showcase

New Post has been published on https://thedigitalinsider.com/students-strive-for-balance-in-a-lively-product-showcase/

Students strive for “Balance!” in a lively product showcase

On an otherwise dark and rainy Monday night, attendees packed Kresge Auditorium for a lively and colorful celebration of student product designs, as part of the final presentations for MIT’s popular class 2.009 (Product Engineering Processes).

With “Balance!” as its theme, the vibrant show attracted hundreds of attendees along with thousands more who tuned in online to see students pitch their products.

The presentations were the culmination of a semester’s worth of work in which six student teams were challenged to design, build, and draft a business plan for a product, in a process meant to emulate what engineers experience as part of a design team at a product development firm.

“This semester, we pushed the six teams to step outside of their comfort zones and find equilibrium between creativity and technical rigor, all as they embarked on a product engineering process journey,” said 2.009 lecturer Josh Wiesman.

Trying to find a balance

The course, known on campus as “two-double-oh-nine,” marks a colorful end to the fall semester on campus. Each team, named after a different color, was given mentors, access to makerspaces, and a budget of $7,500 to turn their ideas into working products. In the process, they learned about creativity, product design, and teamwork.

Various on-stage demonstrations and videos alluded to this year’s theme, from balance beam walks to scooter and skateboard rides.

“Balance is a word that can be used to describe stability, steadiness, symmetry, even fairness or impartiality,” said Professor Peko Hosoi, who co-instructed the class with Wiesman this semester. “Balance is something we all strive for, but we rarely stop to reflect on. Tonight, we invite you to reflect on balance and to celebrate the energy and creativity of each student and team.”

Safety first

The student products spanned industries and sectors. The Red Team developed a respirator for wildland firefighters, who work to prevent and control forest fires by building “fire lines.” Over the course of long days in challenging terrain, these firefighters use hand tools and chainsaws to create fire barriers by digging trenches, clearing vegetation, and other work based on soil and weather conditions. The team’s respirator is designed to comfortably rest on a user’s face and includes a battery-powered air filter the size of a large water bottle that can fit inside a backpack.

The mask includes a filter and a valve for exhalations, with a hose that connects to the blower unit. Team members said their system provides effective respiratory protection against airborne particles and organic vapors as users’ work. Each unit costs $40 to make, and the team plans to license the product to manufacturers, who can sell directly to fire departments and governments.

The Purple Team presented Contact, a crash-detection system designed to enhance safety for young bicycle riders. The device combines hardware and smart algorithms to detect accidents and alert parents or guardians. The system includes features like a head-sensing algorithm to minimize false alerts, plus a crash-detection algorithm that uses acceleration data to calculate injury severity. The compact device is splashproof and dustproof, includes Wi-Fi/LTE connectivity, and can run for a week on a single charge. With a retail price of $75 based on initial production of 5,000 units, the team plans to market the product to schools and outdoor youth groups, aiming to give young riders more independence while keeping them safe.

On ergonomics and rehabilitation

The Yellow Team presented an innovative device for knee rehabilitation. Their prototype is an adjustable, wearable device that monitors patients’ seated exercises in real-time. The data is processed by a mobile app and shared with the patient’s physical therapist, enabling tailored feedback and adjustments. The app also encourages patients to exercise each day, tracks range of motion, and gives therapists a quick overview of each patient’s progress. The product aims to improve recovery outcomes for postsurgery patients or those undergoing rehabilitation for knee-related injuries.

The Blue Team, meanwhile, presented Band-It, an ergonomic tool designed to address the issue of wrist pain among lobstermen. With their research showing that among the 20,000 lobstermen in North America, 1 in 3 suffer from wrist pain, the team developed a durable and simple-to-use banding tool. The product would retail for $50, with a manufacturing cost of $10.50, and includes a licensing model with 10 percent royalties plus a $5,000 base licensing fee. The team emphasized three key features: ergonomic design, simplicity, and durability.

Underwater solutions

Some products were designed for the sea. The Pink Team presented MARLIN (Marine Augmented Reality Lens Imaging Network), a system designed to help divers see more clearly underwater. The device integrates into diving masks and features a video projection system that improves visibility in murky or cloudy water conditions. The system creates a 3D-like view that helps divers better judge distances and depth, while also processing and improving the video feed in real-time to make it easier to see in poor conditions. The team included a hinged design that allows the system to be easily removed from the mask when needed.

The Green Team presented Neptune, an underwater communication device designed for beginner scuba divers. The system features six preprogrammed messages, including essential diving communications like “Ascend,” “Marine Life,” “Look at Me,” “Something’s Off,” “Air,” and “SOS.” The compact device has a range of 20 meters underwater, can operate at depths of up to 50 meters, and runs for six hours on a battery charge. Built with custom electronics to ensure clear and reliable communications underwater, Neptune is housed in a waterproof enclosure with an intuitive button interface. The communications systems will be sold to dive shops in packs of two for $800. The team plans to have dive shops rent the devices for $15 a dive.

“Product engineers of the future”

Throughout the night, spectators in Kresge cheered and waved colorful pompoms as teams demonstrated their prototypes and shared business plans. Teams pitched their products with videos, stories, and elaborate props.

In closing, Wiesman and Hosoi thanked the many people behind the scenes, from lab instructors and teaching assistants to those working to produce the night’s show. They also commended the students for embracing the rigorous and often chaotic coursework, all while striving for balance.

“This all started a mere 13 weeks ago with ideation, talking to people from all walks of life to understand their challenges and uncover problems and opportunities,” Hosoi said. “The class’s six phases of product design ultimately turned our students into product engineers of the future.”

#000#3d#accidents#air#alerts#algorithm#Algorithms#America#app#augmented reality#battery#battery-powered#beam#Blue#Building#Business#Classes and programs#Color#communication#communications#connectivity#course#crash#creativity#Dark#data#Design#detection#development#devices

2 notes

·

View notes

Text

MS Eccentric Reducer from Delhi Supplier at Lowest Price

In industrial piping systems, maintaining a steady flow of liquids and gases is crucial for operational efficiency. The MS Eccentric Reducer serves as a vital component, facilitating smooth transitions between pipes of different diameters while preventing sediment buildup. If you're looking for the lowest prices for MS Eccentric Reducers in India, Udhhyog stands out as your premier supplier based in Delhi.

What is an MS Eccentric Reducer?

An MS Eccentric Reducer is a pipe fitting that connects two pipes of differing diameters, maintaining a flat bottom on one side to minimize the risk of sediment accumulation. This design is especially beneficial in applications where solids can settle, such as in wastewater management or in systems handling slurries. The durable construction and precise engineering of these reducers ensure they can handle varying pressures and temperatures effectively.

Key Features of MS Eccentric Reducers

Optimal Fluid Flow: The eccentric design allows for a continuous flow path, reducing turbulence and ensuring efficient movement of fluids.

Durable Construction: Made from high-quality mild steel, these reducers are engineered for strength and reliability under demanding conditions.

Leak-Proof Joints: The butt weld design ensures a robust seal, minimizing the risk of leaks in high-pressure applications.

Versatile Applications: Suitable for use in various industries, including oil and gas, water treatment, and chemical processing.

Cost-Effective: Offering a combination of quality and affordability, these reducers provide significant value to your piping systems.

Applications of MS Eccentric Reducers

Wastewater Treatment: Essential for preventing sedimentation in wastewater systems, ensuring continuous and efficient fluid flow.

Oil and Gas Pipelines: Used to connect varying pipe sizes while maintaining flow and pressure integrity.

Chemical Processing: Facilitates smooth transitions in chemical plants, helping to streamline processes and reduce downtime.

HVAC Systems: In HVAC applications, they help maintain balanced airflow and efficient pressure management.

Why Choose Udhhyog as Your Supplier?

At Udhhyog, we are dedicated to providing high-quality MS Eccentric Reducers at the lowest prices in India. Here’s why you should choose us:

Quality Assurance: Our reducers are manufactured under stringent quality control standards, ensuring they meet the highest industry benchmarks.

Competitive Pricing: Udhhyog offers some of the best prices in the market, allowing you to optimize your procurement costs without compromising on quality.

Timely Delivery: Based in Delhi, we provide prompt delivery services across India, ensuring you receive your products when you need them.

Extensive Product Range: We offer a wide array of industrial fittings, flanges, and valves, making us a comprehensive supplier for all your piping requirements.

Customer-Centric Approach: Our team is committed to understanding your specific needs and providing tailored solutions to enhance your operational efficiency.

Order Your MS Eccentric Reducers Today

When you choose Udhhyog as your supplier for MS Eccentric Reducers, you gain access to high-quality products at the lowest prices in India. Whether you’re working on large-scale industrial projects or specific applications, we are here to support you with reliable and effective solutions.

#MSEccentricReducer#PipeFittings#IndustrialPiping#Udhhyog#EccentricReducerIndia#LowestPriceIndia#DelhiSupplier#SteelPipeFittings#CostEffectiveSolutions#MSPipeFittings

2 notes

·

View notes

Text

Control Valves MarketStudy, Competitive Strategies by 2029

#Control Valves Market#Control Valves Market trends#Control Valves Market size#Control Valves Market growth

0 notes

Text

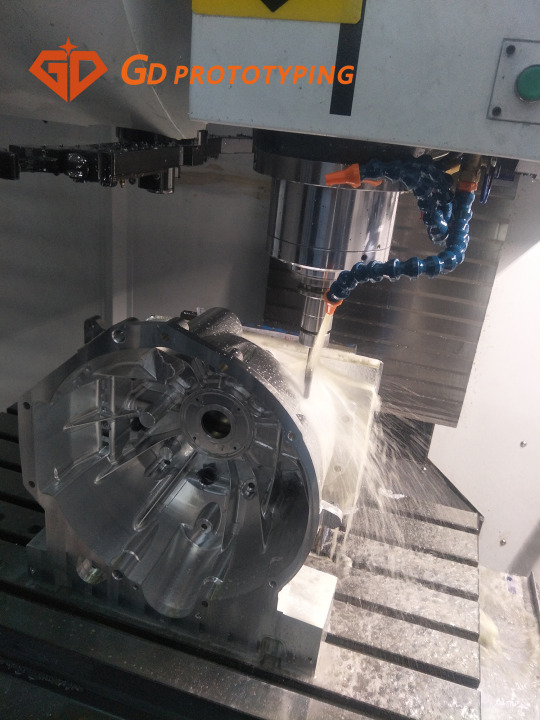

CNC Machining for Aerospace Products

Precision CNC machining of aeronautical parts, as an indispensable part of the modern aeronautical industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous progress of science and technology and the rapid development of the aviation industry, precision CNC machining technology is also constantly optimised and innovated to meet the more demanding aerospace parts machining needs.

Why is CNC important in the aerospace industry?

There is very high and even demanding requirements in aerospace industry for structural design, functionality, performance, product quality and reliability. A large number of new materials and structures were first applied to aircraft components. National defence needs and market competition require a significant reduction in the development and production cycles of space products. In addition, the average cost of the final product needs to be constantly reduced, thus placing higher demands on the aerospace manufacturing industry and requiring advanced manufacturing technologies. Modern CNC machining is a key part of advanced manufacturing technology and has become a decisive key technology, especially in aerospace manufacturing. The following advantages of CNC machining services make them important in the aerospace industry: ①It is the process of synthesising a variety of advanced technology types, including computer technology, communication technology, modern manufacturing technology, digital control technology and so on. ②During CNC machining, the development of a new product and the machining of another batch can be realised by simply changing the settings and parameters of the CNC machine, greatly increasing automation and flexibility. ③Multiple CNC machining can be done automatically on a single machine or in a single clamping, greatly reducing machining time and production cycle time, as well as increasing efficiency. ④CNC machining technology improves the accuracy and precision of aerospace products, reduces or minimises manufacturing errors and results in CNC aircraft parts of higher quality and durability. ⑤Most materials for aerospace components need to be cut and machined during the manufacturing process.

CNC Aircraft Part Features and Application

What are aerospace products? Aircraft can be classified by structure into fuselage, engines, on-board equipment and components, including wings, large wall and tail frames, casings, valve bodies, hydraulic valves, optical tubes, rotor blades, fasteners, connectors, etc. ①Aircraft engine parts: Aircraft engine is one of the core components of the aircraft, the machining accuracy and performance of its parts directly affect the performance and safety of the entire aircraft. ②Fuselage Structural Components: Structural components are the backbone of the aircraft and are subject to a variety of complex loads. Precision CNC machining technology enables high-precision machining of fuselage structural parts, such as beams, frames, plates and other components, to ensure the stability and reliability of their dimensions and shapes. ③Avionics equipment parts: With the continuous development of avionics technology, avionics are more and more widely used in aircraft. Precision CNC machining technology enables high-precision machining of avionics parts, such as circuit boards, connectors and other components, to ensure their accuracy and reliability.

The main features of CNC machining of aerospace parts are as follows:

①High performance: use of new hard-to-machine materials such as titanium ②High Precision: Aerospace parts require a high degree of precision, and any small error may affect the performance and safety of the entire aircraft. Precision CNC machining technology meets the aerospace industry's need for high precision by machining in the micron level of accuracy, ensuring that the size and shape of the part is exactly as designed. ③High Efficient: Precision CNC machining technology can greatly improve productivity by automating and controlling the machining process. After one programming, the CNC machine can run continuously, reducing manual intervention time and increasing production speed. ④Flexibility: Parts in the aerospace industry are varied and complex in shape. Precision CNC machining technology can be quickly adapted to the machining needs of different parts by changing tools and adjusting the programme, without the need for cumbersome manual adjustments, and is suitable for small batch and multi-species production modes. ⑤Lightweight: Extensive use of thin-walled structures. ⑥Consistency: In mass production, part consistency is critical. Precision CNC machining technology ensures that the machining parameters of each part are exactly the same, avoiding quality fluctuations caused by human factors, thus ensuring product consistency and stability. ⑦Reliability and economy: Increasingly stringent quality and cost controls. ⑧Environmental protection and energy saving: The future of precision CNC machining of aerospace parts will pay more attention to environmental protection and energy saving. Adopting more energy-saving and environmentally friendly materials and processes to reduce resource waste and environmental pollution and realise green manufacturing.

In summary, precision CNC machining of aviation parts, as one of the important technologies in the modern aviation industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous innovation and progress of technology, the future of precision CNC machining of aviation parts will move towards the direction of intelligence, automation, high-speed and high-precision, multi-axis and environmental protection and energy saving, injecting a new impetus for the development of the aviation industry.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#cnc precision machining#aerospace parts#cnc precision#machining parts#aerospace#aviation#aircraft

2 notes

·

View notes

Text

Valves Market is Estimated to Witness High Growth

Valves Market is Estimated to Witness High Growth Owing to Rising Constructional and Infrastructure Development Activities The valves market comprises products such as gate valves, globe valves, check valves, butterfly valves, ball valves and pressure regulating valves which are used to control the flow, pressure and direction of fluids. Valves are extensively used in power plants, refineries, oil & gas, water & wastewater and construction activities. These products play a key role in fluid transportation and management which makes them an integral component across various industrial sectors. Rising infrastructure development projects across both developed and developing nations are augmenting the demand for valves. Moreover, growing pipeline networks for oil & gas transportation is also favoring market growth. The Global valves market is estimated to be valued at US$ 83 Mn in 2024 and is expected to exhibit a CAGR of 3.5% over the forecast period 2024 To 2031. Key Takeaways Key players operating in the valves market are Tyson Foods, Inc., JBS S.A., Pilgrim's Pride Corporation, Wens Foodstuff Group Co. Ltd., BRF S.A., Perdue Farms, Sanderson Farms, Baiada Poultry, Bates Turkey Farm, and Amrit Group. The major players are focusing on capacity expansion plans and mergers & acquisitions to gain market share. Rising population and changing diets are expected to fuel the growth of the poultry sector which presents significant opportunities for valve manufacturers. With the growing poultry industry, demand for processing equipment including valves is also projected to rise substantially over the forecast period. The global valves market is estimated to witness growth across key regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. This can be attributed to surging investments in oil & gas, water & wastewater infrastructure, and industrial development projects worldwide. Emerging economies with high urbanization rates like China and India also offer lucrative prospects for market expansion. Market Drivers The key driver behind the Valves Market Demand is the increasing constructional and infrastructure development activities worldwide. There is huge government focus as well as private investments toward projects such as roadways, railways, metro stations, power generation, water supply, etc. which involves extensive use of valves in various process applications. Further, the rising need for energy and growing focus on rural electrification has boosted investments in power transmission and distribution sector augmenting valves demand.

PEST Analysis

Political: The valves market is regulated by laws pertaining to safety, environmental protection and quality standards. New regulations regarding emissions could impact demand patterns. Economic: Changes in the global and regional economic conditions directly impact spending on industries like oil & gas, energy & power, and water & wastewater management which influences Valves demand. Social: Growing population and urbanization is increasing requirements for water, energy and other infrastructure development which boost the usage of valves. Technological: Advancements in materials and designs of valves are improving efficiency, lowering costs and enabling usage in newer applications. Digitalization is also aiding remote monitoring of industrial valves. The regions concentrating maximum valves market share in terms of Valves Market Size and Trends include North America, Europe and Asia Pacific. North America accounts for a major portion owing to strong presence of end-use industries like oil & gas and significant infrastructure spending. Europe and Asia Pacific are also sizable markets led by Germany, China, India respectively. The fastest growing regional market for valves is expected to be Asia Pacific led by increasing investments in water & wastewater management, power projects and industrial activities in China and India. Rising standards of living and initiatives to improve urban infrastructure will further drive the demand across developing nations in the region.

Get more insights Valves Market

Discover the Report for More Insights, Tailored to Your Language.

French German Italian Russian Japanese Chinese Korean Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Valves Market#Control Valves#Globe Valves#Plug Valves#Gate Valves#Ball Valves#Butterfly Valves

2 notes

·

View notes

Text

Yamaha Celebrates 25th Anniversary of the Revolutionary R1

Yamaha Motor Europe is proud to celebrate the 25th anniversary of the ground-breaking R1 with dedicated activities planned at the Yamaha Racing Experience (YRE). This year the YRE will be held at the legendary Mugello Circuit in Italy on the 21st and 22nd of July and will bring together some of Yamaha's biggest stars and enthusiasts to honour the remarkable legacy of the iconic machine. Since its launch, the Yamaha R1 has redefined standards of performance and innovation in the industry. Its 25-year journey of evolution is a testament to Yamaha's dedication to engineering excellence, which cemented the R1 as an icon of speed, power, and cutting-edge technology that revolutionised the sports bike market. Making its grand entrance in 1998, at the core of the R1 was an innovative, compact, and lightweight 998cc, liquid-cooled, 20-valve, double overhead camshaft, four-cylinder engine which featured a five-valve-per-cylinder head with redesigned valve sizes to boost torque and improved porting. However, the real game-changer came from Project Leader Kunihiko Miwa's ingenious decision to create the world's first vertically stacked gearbox in a production motorcycle, which resulted in a lighter, shorter engine that allowed for a longer swing arm, enhancing traction while maintaining a conventional sports bike wheelbase. In addition to its innovative powertrain, the 1998 R1 introduced an all-new aluminium Deltabox II chassis, a heavily braced alloy swingarm, a Yamaha Monoshock shock absorber, and upside-down 41mm fully adjustable front forks developed in collaboration with Öhlins. This Grand Prix-inspired compact chassis and suspension setup offered unrivalled handling and manoeuvrability, setting a new benchmark for modern sports bikes, with the R1 producing an astonishing 150PS while weighing only 177 kg. The R1's racing success was equally remarkable. At the prestigious Isle of Man TT, the bike made history in 1999 when David Jefferies stormed to the TT Formula One victory, in the process setting a record 121,235 mph lap, before going on to win the Senior race and the Production TT, confirming the R1’s racing pedigree to the world. As Yamaha continued to refine and improve the R1, the 2000 model was launched with revisions to over 250 parts, including engine and chassis enhancements, more aerodynamic bodywork, and a new titanium muffler. Two years later, in 2002, Yamaha introduced the next generation of R1, led by Project Leader Yoshikazu Koike, which showcased a groundbreaking vacuum-controlled fuel injection system that provided refined power output and a new Deltabox III frame which was lighter and yet 30% stronger in torsional rigidity. The year 2004 marked the arrival of the fourth generation R1 featuring new engine with larger bore and shorter stroke and closed-deck cylinder design, as well as fracture-split (FS) connecting rods, RAM-air intake, new under-seat exhausts, revised chassis geometry and a sharpened body design. For the first time a production motorcycle was achieving the 1:1 power to weight ratio, thanks to the 180PS delivered by the completely new power train. The R1 that was unveiled in 2007 boasted Yamaha's innovative YCC-T ride-by-wire throttle system and electronically controlled variable air intake funnels (YCC-I). Project Leader Makato Shimamoto also introduced a new four-valve design motor, slipper clutch, an improved Deltabox frame as well as improved brakes and suspension. Building on its legacy, Yamaha launched the next generation R1 in 2009, featuring a ground-breaking crossplane crankshaft engine, directly derived from Yamaha’s MotoGP M1. This unique design reduced inertia forces and delivered a more linear throttle connection. Next to that, Development Leader Toyoshi Nishida introduced twin fuel injectors, a new lightweight aluminium Deltabox frame, cast magnesium subframe and cutting-edge electronics. This model set the standard for handling and performance in the world of racing in 2009, highlighted by the incredible performance of American Ben Spies in WorldSBK, with the rookie recording 14 wins in 28 races to claim the 2009 title. Reinforcing the competitiveness of the R1 that year, the YART Yamaha EWC team was crowned Endurance World Champions, while Leon Camier won 19 out of 26 races on his way to lifting the British Superbike Championship, and Katsuyuki Nakasuga clinched his first Japanese Superbike Championship title. Constantly looking to innovate, the 2012 R1 incorporated a traction control system that adjusted ignition timing, fuel delivery, and throttle opening to maintain optimal traction, enhancing drivability and fuel consumption. To mark another ground-breaking step, the 2015 R1 was launched with a powerful 200PS engine and was the first production motorcycle equipped with a six-axis Inertial Measurement Unit (IMU) and electronic support systems – developed and proven in MotoGP. With a dry weight of 179 kg and a host of racing features the 2015 R1 has been a sensation. Project Chief Hideki Fujiwara also introduced the top-of-the-line, limited edition R1M which featured electronically controlled suspension, a lightweight carbon-fibre cowl, and an onboard data logger to cater to the needs of serious racing and track day devotees. The 2018 R1 model offered riders an even more extensive array of sophisticated electronics, and the addition of a Quick Shift System (QSS) with a blipper function for clutchless up and downshifting took the R1 and R1M’s performance on the street and track to the next level. The R1’s handling performance was refined with more progressive mapping on the Lift Control System as well as revised suspension settings – and the Öhlins Electronic Racing Suspension on the R1M featured a revised interface for a more intuitive set-up. For 2020, the R1 featured a CP4 engine with new cylinder head, camshafts and injection system – while the extensive electronic rider aids were refined to ensure even higher levels of controllability. A new EBM (Engine Brake Management) enabled the rider to select one of three different engine braking forces to match riding conditions – and the new Brake Control (BC) system gave added confidence and control when cornering. With revised damping valves and a reduced spring rate, the R1’s 43mm KYB forks provided increased feedback for a more natural handling feeling. And for improved chassis performance and reduced lap times the R1M was equipped with a new rear shock and uprated Öhlins ERS NPX gas pressurised forks. Over recent years, the R1 and R1M have continued to evolve and remain a dominant force on the racing scene, with Pata Yamaha Prometeon Official WorldSBK Team’s Toprak Razgatlıoğlu and Andrea Locatelli leading the charge in the FIM Superbike World Championship. The highlight of which was Razgatlıoğlu’s 2021 WorldSBK Championship winning season that saw the Turkish rider rack up 13 race wins and 16 further podiums on his way to the title, while Italian Locatelli has grown from strength-to-strength on the R1 and has 11 podiums to his name so far. On top of this, the R1 has demonstrated its prowess all over the world, with the Yamaha Factory Racing Team winning the historic Suzuka 8 Hours endurance race four times in a row between 2015-2018, plus Cameron Beaubier (2015, 2016, 2018, 2019, 2020) and Jake Gagne (2021, 2022) securing seven of the last eight AMA Superbike titles. In 2021, Nakasuga would lift an incredible tenth Japanese Superbike Championship, with Tommy Hill (2011), Josh Brookes (2015), Tarran Mackenzie (2021), and Bradley Ray (2022) all being crowned British Superbike Champions on the R1. As the legacy of the R1 continues to grow, Yamaha remains committed to pushing the boundaries of innovation with the introduction of the R1 GYTR. GYTR (Genuine Yamaha Technology Racing) is Yamaha’s in-house specialist racing component division that has been developing performance enhancing technology for over 40 years. Designed specifically for track-day riders and racers who recognise Yamaha’s winning performance and premium quality, the 2023 R1 GYTR is faster and more precise than ever. Manufactured to comply with FIM Stock 1000 regulations, this high-specification machine provides individuals and teams with the ultimate canvas to create their own unique superbike. The R1 GYTR is equipped with over 25 GYTR race specification components including an Akrapovic race exhaust system, racing ECU, wiring harness, GYTR chassis parts, drive system and complete race cowling in primer white – plus much more. The R1 GYTR is available exclusively from GYTR PRO SHOPS. To mark such a momentous anniversary, the Yamaha Racing Experience at Mugello will host the celebration activities for the R1, with the Tuscany circuit, renowned for its fast and challenging track layout that makes it a favourite among riders and fans alike, providing the perfect setting to honour such an incredible machine. Usually the event is exclusive to R1M customers, however the 2023 YRE will be open for the first time to R1 owners to mark this momentous occasion, with two different options available to them to attend. There are 25 spots available to R1 owners for the whole two days program, where they can enjoy the full Yamaha Racing Experience along with the R1M customers – which includes track sessions on both days, the ability to get advises from Yamaha racing technicians to give their bikes the optimum setup, exclusive tours of the Pata Yamaha Prometeon WorldSBK pit box, and much more. Click here to learn more and register for the two-day whole YRE experience. There is also an option for R1 owners to attend just on Saturday, where they can register for up to two track sessions for free and still enjoy the event atmosphere, and go behind the scenes in the Pata Yamaha Prometeon garage. For more information on this option and to register to attend just on Saturday, click here. The track sessions at the YRE will see owners get the chance to meet and ride alongside some of Yamaha’s biggest stars from WorldSBK, including Pata Yamaha Prometon WorldSBK riders Toprak Razgatlıoğlu and Andrea Locatelli, the GYTR GRT Yamaha WorldSBK Team duo of Remy Gardner and Dominique Aegerter, GMT94 Yamaha WorldSBK Team’s Lorenzo Baldassari, Yamaha Motoxracing WorldSBK Team’s Bradley Ray, plus YART Yamaha Official EWC Team’s Niccolò Canepa. The 25th-anniversary celebration at the YRE promises to be an exclusive experience for all R1 and R1M owners to come together and celebrate these iconic machines, with a special exhibition of R1s from across the years and including a collection of some of the most memorable race bikes, with the event showcasing the R1’s enduring legacy in the world of motorcycling. Paolo Pavesio Marketing and Motorsport Director, Yamaha Motor Europe “We are proud to honour the 25th anniversary of the Yamaha R1 in 2023. The R1 has been a game-changer in the world of motorcycles, pushing the boundaries of performance and innovation and constantly evolving to be at the pinnacle of the racing world. It is a bike that has redefined what is possible during the last 25 years with technology and innovations derived directly from MotoGP and WSBK. The Yamaha Racing Experience at Mugello will be something special this year, the perfect opportunity to salute such an iconic machine together with our customers and some of Yamaha's biggest stars.” For more Yamaha Motorcycles UK news check out our dedicated page Yamaha Motorcycles UK or head to the official Yamaha Motorcycles UK website yamaha-motor.eu/gb/en/ Read the full article

2 notes

·

View notes

Link

#market research future#control valve market size#control valve market analysis#control valve market growth#control valve market forecast

0 notes

Text

Butterfly Valve vs Ball Valve: Comparison Guide

Butterfly Valve vs. Ball Valve: How to Choose the Right One for Your Application

When selecting valves for industrial systems, engineers and procurement managers often face a common dilemma: butterfly valve vs. ball valve. Both valves are widely used across industries, but their structural designs, performance characteristics, and cost implications differ significantly. As a leading valve manufacturer in China, we break down the key factors—structure, size, price, application suitability, and future trends—to help you make an informed decision.

1. Structural Differences: Simplicity vs. Precision

A butterfly valve features a disc mounted on a rotating shaft. When open, the disc aligns with the flow direction; when closed, it rotates 90° to block the medium. Its simple design makes it lightweight, compact, and easy to install. However, the disc’s presence in the flow path can create turbulence, making it less ideal for high-precision throttling.

Ball Valve Structure:

A ball valve uses a perforated, rotating sphere to control flow. When open, the hole aligns with the pipeline, offering minimal flow resistance. When closed, the sphere rotates to block the medium completely. The full-bore design of many ball valves ensures smooth flow with minimal pressure drop, making them excellent for precise shut-off applications.

Key Takeaway: Butterfly valves are simpler and lighter, while ball valves provide tighter sealing and better flow control.

2. Size and Installation Considerations

Butterfly Valves:

- Ideal for large-diameter pipelines (2” to 48” or more). Their compact design requires less space, reducing installation costs.

- Commonly used in water treatment, HVAC systems, and low-pressure chemical applications.

Ball Valves:

- Best suited for small to medium-sized pipelines (0.5” to 12”).

- Preferred in high-pressure systems like oil and gas, where leak-tight sealing is critical.

*Pro Tip*: For large-scale projects requiring cost-effective solutions, Chinese valve manufacturers often recommend butterfly valves due to their scalability and lower material costs.

3. Price Comparison: Balancing Budget and Performance

Butterfly Valve Price:

- Generally 30–50% cheaper than ball valves of the same size. - Lower manufacturing costs (fewer components) and reduced maintenance expenses make them budget-friendly for large installations.

Ball Valve Price:

- Higher initial cost due to complex machining and premium materials (e.g., stainless steel, brass). - Long-term savings in high-pressure systems due to durability and minimal leakage risks.

*Insight*: Sourcing from a reliable valve supplier in China can help mitigate costs without compromising quality.

4. Application-Based Selection Guidelines

Choose a Butterfly Valve If:

- Your system operates at low to moderate pressures (up to 150 psi).

- You need quick operation (quarter-turn actuation) for throttling or isolation.

- Space or weight constraints exist (e.g., shipbuilding, irrigation systems).

Choose a Ball Valve If:

- Your application demands zero leakage (e.g., natural gas pipelines).

- You require precise flow control or handling of viscous fluids.

- The system operates under high pressure or extreme temperatures.

Industry Examples:

- Butterfly valves dominate in water distribution and food processing.

- Ball valves are standard in oil refineries, pharmaceutical plants, and steam systems.

5. Future Trends: Market Demand and Innovations

Butterfly Valves:

- Rising demand in water conservation and renewable energy projects (e.g., solar thermal plants).

- Advancements in polymer-coated discs improve chemical resistance, expanding their use in corrosive environments.

Ball Valves:

- Growing adoption in LNG and hydrogen energy systems, driven by stricter emission regulations.

- Smart valves with IoT sensors are gaining traction, enabling predictive maintenance.

*China’s Role*: As the world’s largest valve manufacturer, China continues to lead in cost-effective production and R&D, making both butterfly and ball valves more accessible globally.

Conclusion: Partner with the Right Manufacturer

Understanding the differences between butterfly and ball valves ensures optimal system performance and cost efficiency. For large-scale, low-pressure applications, butterfly valves offer unmatched affordability. For high-pressure, precision-critical systems, ball valves are worth the investment.

When sourcing, collaborate with a trusted valve manufacturer in China to leverage competitive pricing, customization options, and adherence to international standards. Whether you prioritize price, durability, or innovation, the right choice depends on your specific operational needs.

By evaluating structure, size, cost, and future trends, you can select the valve that maximizes ROI and longevity for your project.

#ball valve manufacturers in india#ball valve suppliers#ball valve#butterfly valve#butterfly valve suppliers#butterfly valve manufacturer in china#ball valve manufacturer in china

0 notes

Text

How Pressure Reducing Valves Work: A Complete Guide

Introduction

Pressure Reducing Valves (PRVs) play a crucial role in maintaining optimal pressure levels in plumbing, industrial, and HVAC systems. They protect equipment, prevent leaks, and enhance efficiency by regulating high inlet pressure to a steady, lower outlet pressure.

What is a Pressure Reducing Valve?

A Pressure Reducing Valve (PRV) is a mechanical device that controls fluid pressure by automatically reducing a higher inlet pressure to a lower, stable outlet pressure.

Key Features:

Regulates and stabilizes pressure

Prevents damage due to excessive pressure

Ensures smooth operation of pipelines and equipment

How Does a Pressure Reducing Valve Work?

PRVs operate using a spring-loaded diaphragm or piston mechanism that adjusts flow to maintain a steady pressure level.

Working Steps:

High-pressure fluid enters the valve.

Spring-loaded diaphragm or piston detects pressure changes.

The valve opening adjusts to control the pressure.

Steady, reduced pressure is maintained at the outlet.

Components of a Pressure Reducing Valve

Component Function Body Houses the internal components Diaphragm/ Piston Senses pressure and adjusts flow Spring Mechanism Controls valve opening based on pressure Adjusting Screw Allows manual pressure adjustment Outlet Port Delivers controlled, reduced pressure

Types of Pressure Reducing Valves

1. Direct-Acting PRV

Simple design with a self-contained mechanism

Best for residential and low-flow applications

2. Pilot-Operated PRV

More precise and responsive to pressure variations

Suitable for industrial and high-flow systems

3. Water Pressure Reducing Valve

Controls water supply pressure to prevent pipe damage

4. Steam Pressure Reducing Valve

Used in boiler systems to maintain safe steam pressure

5. Gas Pressure Reducing Valve

Regulates gas pressure for industrial applications

Applications of Pressure Reducing Valves

PRVs are widely used across industries to enhance operational efficiency. Industry Application Plumbing Water supply systems HVAC Boiler and cooling systems Manufacturing Hydraulic and pneumatic systems Oil & Gas Gas distribution networks Agriculture Irrigation pressure control Fire Protection Fire suppression systems

Benefits of Pressure Reducing Valves

Protects Equipment: Prevents overpressure damage.

Enhances Efficiency: Optimizes system performance.

Reduces Wastage: Minimizes water and energy loss.

Ensures Safety: Prevents pipe bursts and leaks.

How to Select the Right PRV

Determine System Pressure Requirements.

Choose the Correct Valve Type (Direct-Acting, Pilot-Operated, etc.).

Check Material Compatibility (Brass, Stainless Steel, Bronze).

Ensure Compliance with Industry Standards.

Consider Flow Rate and Valve Sizing.

Installation & Maintenance Tips

Installation:

Install PRV in an easily accessible location.

Align the valve with the direction of flow.

Use appropriate fittings for secure installation.

Maintenance:

Inspect regularly for leaks or pressure fluctuations.

Clean diaphragm and internal components periodically.

Replace worn-out seals and springs as needed.

Udhhyog is your go-to source for industry and manufacturing insights, empowering businesses with the latest trends, supplier connections, and growth strategies. We specialize in pipes, steel, manufacturing, and infrastructure, helping industries stay ahead in a competitive market. Follow us for updates, expert insights, and collaboration opportunities!

FAQs

1. What is the function of a pressure reducing valve?

A PRV regulates high inlet pressure to a lower, stable outlet pressure, ensuring system safety and efficiency.

2. How do I know if my PRV is malfunctioning?

Common signs include fluctuating pressure, water hammer noises, and leaks around the valve.

3. Can a PRV be manually adjusted?

Yes, most PRVs feature an adjustment screw to fine-tune the outlet pressure.

4. Where are PRVs commonly used?

They are used in plumbing, HVAC, steam, gas, and industrial systems.

5. How long does a pressure reducing valve last?

A well-maintained PRV can last between 5 to 10 years, depending on usage conditions.

0 notes

Text

Cylinder Deactivation System Market Trends: Growth, Share, Value, Size, and Analysis

"Cylinder Deactivation System Market Size And Forecast by 2029

According to Data Bridge Market Research analyses that the cylinder deactivation system market would exhibit a CAGR of 3.40% for the forecast period and is expected to reach the USD 5.99 billion by 2029.

Cylinder Deactivation System Market is making waves in the industry with its latest advancements and market-driven strategies. As a leading player, Engine Efficiency Technology Market continues to push boundaries by offering cutting-edge solutions that cater to evolving consumer demands. With a strong focus on innovation, Cylinder Deactivation System Market has successfully expanded its global footprint, providing businesses with high-quality services and products. The rapid growth of Variable Cylinder Management Market is fueled by technological advancements, customer-centric approaches, and strategic partnerships. As Cylinder Deactivation System Market strengthens its position, it remains committed to delivering value-driven solutions that enhance market efficiency and growth.

Fuel-Saving Cylinder Tech Market's impact on the industry is undeniable, with continuous efforts to enhance product offerings and service quality. By leveraging data-driven insights and advanced technologies, Cylinder Deactivation System Market ensures it stays ahead of market trends. The adaptability of Smart Cylinder Control Market has allowed it to address diverse industry challenges while maintaining a competitive edge. Companies relying on Cylinder Deactivation System Market benefit from its expertise, robust infrastructure, and commitment to excellence. With increasing global demand, Eco-Friendly Engine Optimization Market is poised for sustained growth, driving innovation and transformation across various sectors.

Our comprehensive Cylinder Deactivation System Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-cylinder-deactivation-system-market

**Segments**

- **By Component** - Engine Control Module - Solenoid Controlled Valve - Hydraulic Lifter - Others - **By Vehicle Type** - Passenger Cars - Commercial Vehicles - **By Sales Channel** - Original Equipment Manufacturers (OEMs) - Aftermarket

The global cylinder deactivation system market is segmented based on components, vehicle types, and sales channels. In terms of components, the market is divided into engine control modules, solenoid controlled valves, hydraulic lifters, and others. Engine control modules play a crucial role in the functioning of cylinder deactivation systems by ensuring seamless coordination among different components. Solenoid controlled valves help in regulating the flow of oil and hydraulic lifters assist in activating and deactivating cylinders as needed. When it comes to vehicle types, the market caters to both passenger cars and commercial vehicles. Passenger cars are increasingly adopting cylinder deactivation systems to enhance fuel efficiency and reduce emissions. On the other hand, commercial vehicles are also adopting these systems to improve overall performance. Sales channels in the market include original equipment manufacturers (OEMs) and the aftermarket. OEMs are crucial in integrating these systems into new vehicles, whereas the aftermarket segment provides components for retrofitting existing vehicles.

**Market Players**

- Bosch - Schaeffler AG - Eaton - Denso Corporation - Hyundai Mobis - Delphi Technologies - Hitachi Automotive Systems - Continental AG - Mitsubishi Electric Corporation - Valeo - BorgWarner Inc.

Key market players in the global cylinder deactivation system market include Bosch, Schaeffler AG, Eaton, Denso Corporation, Hyundai Mobis, Delphi Technologies, Hitachi Automotive Systems, Continental AG, Mitsubishi Electric Corporation, Valeo, and BorgWarner Inc. These companies are actively involved in research and development activities to enhance the efficiency and effectiveness of cylinder deactivation systems. They are also focusing on strategic partnerships and collaborations to expand their market presence and cater to a wider customer base. With the growing emphasis on sustainability and fuel efficiency, these market players are at the forefront of developing advanced technologies for the automotive industry.

https://www.databridgemarketresearch.com/reports/global-cylinder-deactivation-system-market The global cylinder deactivation system market is expected to witness significant growth in the coming years due to the increasing focus on fuel efficiency and emission reduction in the automotive industry. One of the key trends shaping the market is the integration of advanced technologies such as engine control modules, solenoid controlled valves, and hydraulic lifters to enhance the performance of cylinder deactivation systems. These components play a crucial role in optimizing engine operations and improving overall vehicle efficiency. The adoption of cylinder deactivation systems is particularly high in passenger cars, driven by the need to comply with stringent emission regulations and meet consumer demands for environmentally friendly vehicles.

Commercial vehicles are also embracing cylinder deactivation systems to achieve better fuel economy and performance. The market players, including Bosch, Schaeffler AG, Eaton, and Denso Corporation, are at the forefront of innovation in this space, developing cutting-edge solutions to meet the evolving needs of the automotive industry. These companies are investing heavily in research and development to enhance the effectiveness of cylinder deactivation systems and stay competitive in the market. Strategic partnerships and collaborations play a vital role in their growth strategy, enabling them to expand their product offerings and geographical reach.

The aftermarket segment is gaining traction in the cylinder deactivation system market, offering opportunities for component suppliers and service providers to cater to the replacement and retrofitting needs of existing vehicle owners. As consumers seek cost-effective ways to enhance their vehicle's efficiency, the aftermarket sales channel is likely to witness steady growth in the coming years. Moreover, the increasing awareness regarding the benefits of cylinder deactivation systems, such as reduced fuel consumption and lower emissions, is driving the demand for these systems across different vehicle types and sales channels.

Overall, the global cylinder deactivation system market is poised for substantial growth, driven by technological advancements, regulatory mandates, and shifting consumer preferences towards eco-friendly transportation solutions. Market players need to stay ahead of these trends by innovating their product offerings, expanding their distribution networks, and strengthening their partnerships to capitalize on the lucrative opportunities in the automotive industry. By aligning their strategies with market demands and leveraging their expertise in cylinder deactivation technology, companies can secure a competitive edge and position themselves for long-term success in this dynamic market landscape.The global cylinder deactivation system market is witnessing robust growth driven by the increasing emphasis on fuel efficiency and emission reduction in the automotive sector. Key market segments including components, vehicle types, and sales channels are shaping the industry dynamics. Components such as engine control modules, solenoid controlled valves, and hydraulic lifters are integral to the efficient functioning of cylinder deactivation systems. These components work together to optimize engine operations, boost vehicle performance, and reduce emissions. The market caters to both passenger cars and commercial vehicles, with passenger cars leading the adoption of cylinder deactivation systems to meet emission regulations and consumer demand for eco-friendly vehicles. Commercial vehicles are also embracing these systems to enhance fuel economy and overall performance.

Market players like Bosch, Schaeffler AG, Eaton, and Denso Corporation are driving innovation in the cylinder deactivation system market through research and development efforts. These companies are investing in advanced technologies to enhance system efficiency and effectiveness, meeting the evolving needs of the automotive industry. Strategic partnerships and collaborations are instrumental in expanding their market presence and product offerings. The aftermarket segment is gaining traction as consumers seek cost-effective solutions to improve vehicle efficiency, providing opportunities for component suppliers and service providers to cater to replacement and retrofitting needs. Awareness about the benefits of cylinder deactivation systems, including reduced fuel consumption and emissions, is fueling demand across various vehicle types and sales channels.

Looking ahead, the global cylinder deactivation system market is poised for significant growth driven by technological advancements, regulatory mandates, and shifting consumer preferences towards sustainable transportation solutions. Market players need to focus on continuous innovation, expanding distribution networks, and fostering strategic partnerships to capitalize on emerging opportunities in the automotive industry. By aligning their strategies with market trends and leveraging their expertise in cylinder deactivation technology, companies can gain a competitive edge and position themselves for long-term success in this dynamic market landscape. The integration of advanced technologies, increasing focus on sustainability, and the rising demand for fuel-efficient vehicles further underscore the promising outlook for the global cylinder deactivation system market.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Cylinder Deactivation System Market : https://www.databridgemarketresearch.com/reports/global-cylinder-deactivation-system-market/companies

Key Questions Answered by the Global Cylinder Deactivation System Market Report:

What is the current state of the Cylinder Deactivation System Market, and how has it evolved?

What are the key drivers behind the growth of the Cylinder Deactivation System Market?

What challenges and barriers do businesses in the Cylinder Deactivation System Market face?

How are technological innovations impacting the Cylinder Deactivation System Market?

What emerging trends and opportunities should businesses be aware of in the Cylinder Deactivation System Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-clinical-laboratory-services-markethttps://www.databridgemarketresearch.com/reports/middle-east-and-africa-customized-premixes-markethttps://www.databridgemarketresearch.com/reports/middle-east-and-africa-fire-protection-materials-markethttps://www.databridgemarketresearch.com/reports/global-intelligent-power-distribution-unit-pdu-markethttps://www.databridgemarketresearch.com/reports/global-dental-instrument-delivery-systems-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 997

✉ Email: [email protected]"

#Engine Efficiency Technology Market#Variable Cylinder Management Market#Fuel-Saving Cylinder Tech Market#Smart Cylinder Control Market#Eco-Friendly Engine Optimization Market#Advanced Combustion Control Market#Automotive Cylinder Shutoff Market#Adaptive Engine Performance Market#Powertrain Efficiency Solutions Market#Automotive Fuel Economy Market

0 notes